Energy Wastage

Harford Energy Wastage Solutions provide comprehensive reporting and insights for manufacturers, assisting factories in reducing energy wastage at multiple levels.

Energy Wastage & Tracking Solutions

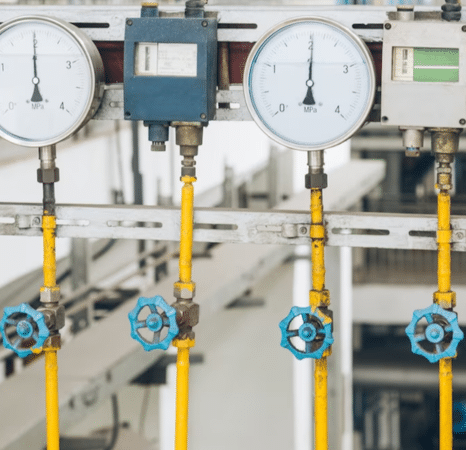

Harford energy wastage reduction solutions enable real-time energy monitoring and reduction in manufacturing. Accurately track gas, air, water, electricity, and other forms of energy to identify savings opportunities. We provide comprehensive reporting and insights for manufacturers and help factories reduce energy wastage at multiple levels and to drive sustainable practices and enhance manufacturing performance.

Optimising Equipment Performance & Reduce Energy Wastage

By implementing energy wastage reduction solutions, companies can identify energy-intensive areas, optimise equipment performance, and reduce energy wastage. This leads to significant cost savings, improved environmental sustainability, and compliance with energy efficiency regulations. Enhanced energy management also supports predictive maintenance, prolongs equipment lifespan, and enhances overall operational reliability.

Real-time Actionable Insights

Harford Control’s energy wastage reduction solutions utilise cutting-edge technology to capture and analyse various forms of energy (gas, air, water, electricity, etc.) from machines, systems, and processes. By identifying specific opportunities for energy savings, our solutions provide real-time actionable insights to inform factories power off idle machines and foster sustainability practices.

Energy Tracking Solutions for A Range of Industries

Industries such as FMCG, Food & Beverage, Health & Beauty, Pharmaceutical and chemical heavily rely on energy-intensive processes. Harford Control’s energy wastage reduction solutions play a vital role in these sectors by helping companiesreduce energy wastage, reduce carbon footprint, and become more sustainable. By accurately monitoring energy usage and implementing energy-saving measures, businesses can enhance their competitive edge, ensure regulatory compliance, and contribute to a greener future.

Energy-Saving Opportunity Identification

Accurately measure energy usage from machines and identify specific opportunities for energy savings.

Comprehensive Energy Wastage Tracking

Monitor various energy forms (gas, air, water, electricity) for efficient consumption management.

Granular Monitoring

Track energy wastage at different levels (site, hall, departments) and specific areas (production lines, machines) for targeted optimisation.

Machine-Level Control

Optimise energy consumption by powering off idle machines, reducing energy wastage.

Seamless Integration

Integrate the energy tracking system with existing machinery, allowing for data extraction and integration into the overall manufacturing process.

Why Work with Harford Control

Harford’s energy tracking solutions stand out due to our ability to measure energy usage at various levels, including granular site, department, line, area, and individual machines. This level of detailed tracking sets us apart from many other solutions in the market, providing in-depth insights into energy consumption.

With over half a century of continuous development in performance improvement systems, we remain at the forefront of real-time factory floor MES technology. By actively listening to our clients’ needs, we continuously enhance and refine our energy tracking solutions to meet their evolving requirements.

Who We Have Helped

FAQs

-

How can energy wastage be reduced in manufacturing processes?

Energy wastage in manufacturing processes can be reduced through various measures. These include conducting energy audits to identify inefficiencies, optimizing equipment and machinery for energy efficiency, implementing energy management systems, utilizing renewable energy sources, and promoting energy-conscious behaviours among employees. By adopting energy-saving practices, manufacturers can minimize wastage and lower energy costs while reducing their environmental impact.

-

What are the common causes of energy wastage in manufacturing?

Energy wastage in manufacturing can occur due to various factors. These include inefficient equipment operation, poor maintenance practices, air leaks, overuse of lighting, improper insulation, and ineffective energy management systems. Lack of employee awareness and engagement in energy-saving practices can also contribute to wastage. Identifying and addressing these causes can help manufacturers reduce energy wastage and improve overall energy efficiency.

-

How can energy tracking benefit manufacturing companies?

Energy tracking provides valuable insights into energy consumption patterns, identifies areas of high energy usage, and highlights opportunities for optimization. By tracking energy data in real time, manufacturing companies can monitor energy performance, set energy-saving targets, and identify anomalies or inefficiencies. This data-driven approach enables informed decision-making, promotes energy efficiency initiatives, and helps reduce energy costs and environmental impact.

-

How can manufacturers improve energy efficiency in their operations?

Manufacturers can improve energy efficiency in their operations through various strategies. These may include implementing energy management systems, conducting energy audits, upgrading to energy-efficient equipment, optimizing production processes, improving insulation, utilizing energy-saving technologies, and promoting employee awareness and engagement in energy conservation practices. By adopting a holistic approach to energy efficiency, manufacturers can reduce energy wastage and achieve long-term cost savings and sustainability.

-

What are the benefits of reducing energy wastage in manufacturing?

Reducing energy wastage in manufacturing brings several benefits. It helps lower energy costs, improve operational efficiency, and enhance environmental sustainability. By optimizing energy usage, manufacturers can reduce their carbon footprint, comply with regulatory requirements, and enhance their brand reputation. Additionally, energy-efficient operations contribute to resource conservation, minimize reliance on non-renewable energy sources, and support long-term sustainability goals.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.