Line Automation

Harford Line Automation Solutions enable manufacturers to achieve precise product labelling, rapid line setup upon changeovers, minimise operator error, optimise machine interaction and coordination to facilitate seamless data exchange. These solutions encompass Autocoding, Machine Integration, and ERP/SAP Integration.

A Range of Line Automation Solutions

Harford Control’s line automation solutions can help you achieve industrial optimisation and compliance. Autocoding, Label Verification, Machine Integration, and ERP/SAP connectivity are all parts of our full solution, which improves traceability, reduces human errors, and streamlines operations.

Regulatory compliance and seamless data management are ensured for FMCG, Food & Beverage, Health & Beauty, Pharmaceutical, and Chemical manufacturers with features such as barcode and date coding, live peripheral monitoring, allergen control, auto laboratory triggers, and non-conformance prevention (error proofing).

Autocoding, Machine Integration, ERP/SAP Integration

Autocoding ensures accurate and efficient product labelling and coding, machine integration optimises the interaction and coordination between machines, and ERP/SAP integration facilitates seamless data exchange and process synchronisation. These solutions enhance operational efficiency, minimise errors, and provide real-time insights for better decision-making.

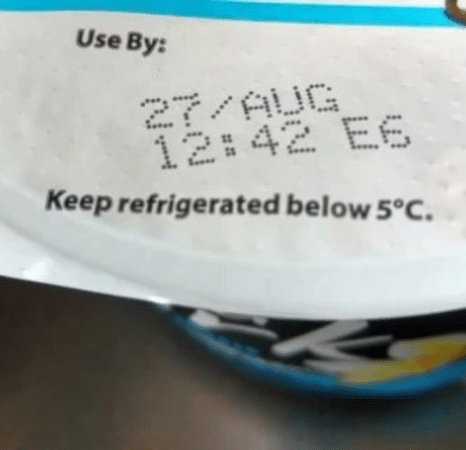

Autocoding - Efficient Product Labelling

Harford Autocoding contains production line automation, accurate date coding set up, label verification with in-line barcode scanners configured to ensure the highest validation of packs. This way, we can help manufacturers to eliminate risks, prevent non-conformances, minimise human errors and avoid unnecessary wastage. In the event of a non-conformance during the run, we can activate a line stop and/or a rejection mechanism. Non conformances, rejects and line speeds are all computer reported.

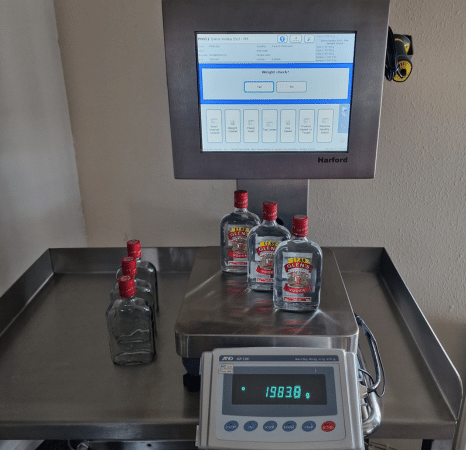

Machine Integration - Optimise Production Workflows

The machine integration solution from Harford Control enables seamless coordination and communication across machines on the production line, improving efficiency, reducing downtime and increasing overall productivity.

With features like auto result capture and connections with inline checkweighers, HPLC and Anton Parr, our integration capabilities enable efficient data exchange and synchronization between machines, streamlining operations for optimal performance.

ERP/SAP Integration - Seamless Data Exchange

Harford solutions are compatible with ERP/SAP systems. Our solutions seamlessly receive schedules and Bill of Materials (BOM) files while giving real-time production updates for accurate stock level adjustments by linking with existing IT solutions. Improve visibility, traceability, and decision-making capabilities for more efficient operations and higher productivity.

Why Work with Harford Control?

Over several decades, Harford Control has worked tirelessly with a wide range of factories across five continents to help optimise their production performance.

With the Harford Manufacturing Execution System (MES) tailored to individual needs, it becomes easier to reduce errors, find the hidden wastage and consequently become more efficient, whilst continuing to deliver consistently high quality products, thereby making each business more profitable and sustainable.

Most manufacturers are facing ever increasing input and transformation costs with few opportunities to increase the output price to their customers (High Street Multiples).

This encourages manufacturers to look more deeply into their production processes to find the hidden costs, eliminate wastage and thereby improve efficiency without compromising quality.

The problem of rising input costs and fixed output costs is nothing new and will not end. Therefore performance improvement to drive down transformation costs must be continuous for the business to sustain its market position and avoid losing its place on supermarket shelves to the competition.

Who We Have Helped

FAQs

-

What is line automation in manufacturing?

Line automation refers to the use of automated systems and technologies to streamline and optimize production processes on manufacturing assembly lines. It involves the integration of various automated equipment, robotics, conveyors, and control systems to enhance efficiency, productivity, and consistency in manufacturing operations.

-

What are the benefits of line automation?

Line automation offers several benefits, including increased production throughput, improved product quality, enhanced operational efficiency, reduced labour costs, and minimized human errors. By automating repetitive tasks and implementing advanced control systems, manufacturers can achieve higher production rates, faster cycle times, and better overall process control.

-

How does line automation improve productivity?

Line automation improves productivity by eliminating manual tasks, reducing cycle times, and enabling continuous operation. Automated systems can perform tasks at a consistent pace without the need for breaks or rest, resulting in higher production throughput. It also allows for better resource allocation, optimized workflow, and improved overall equipment effectiveness (OEE).

-

How does line automation contribute to quality control efforts?

Line automation contributes to quality control efforts by ensuring consistency, accuracy, and traceability in manufacturing processes. Automated systems can perform precise and repeatable tasks, reducing the risk of human errors and variability. They can also incorporate quality checks, inspections, and data collection at various stages, enabling real-time monitoring and proactive quality control measures.

-

Can line automation systems be integrated with existing manufacturing systems?

Yes, line automation systems can be integrated with existing manufacturing systems, such as enterprise resource planning (ERP) systems, production control software, and quality management systems. Integration allows for seamless data exchange, real-time information sharing, and synchronized operations. It enables manufacturers to optimize workflow, track production data, and make data-driven decisions across the manufacturing ecosystem.