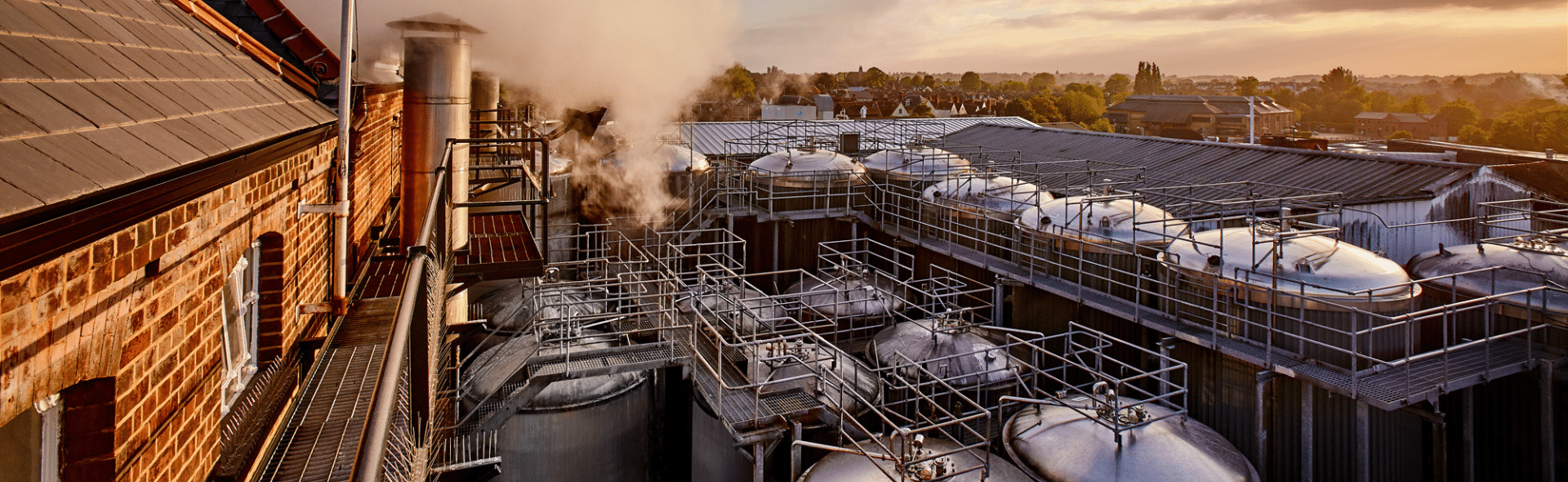

Discover Harford's End-to-End MIS/MES

Collate, analyse and visualise shopfloor data across your manufacturing process. Provide users with actionable insights to facilitate immediate decisions, as well as the analytical tools needed for achieving strategic goals.

-

- Paperless Quality, Lab Quality & Traceability

- Minimise Non-Conformances, Automate Results Analysis & Reduce Errors

Read more

-

- Lab Quality

- Ensure Consistent High Quality & Right First Time, Every Time.

Read more

-

- Wastage Monitoring & Energy Tracking

- Minimise Raw Materials & Labour Wastage. Accurately track Energy Consumption

Read more

-

- Weight Control, Average Quantity & Process Integration

- Reduce Overfill and Ensure Legal Compliance

Read more

-

- OEE, Short Interval Control, Live Reporting, End-to-End Traceability & Centerlining

- Real Time Actionable Information to make Data-Driven Decisions to help Improve Performance.

Read more

-

- Energy Tracking, Material Consumption, Labour Monitoring & End-to-End Traceability

- To Improve Resource Utilisation & Enhance Process Control

Read more

-

- Autocoding, Machine & ERP Integration

- Ensure Correct Labelling, Traceability & Reduce Human Error through Automation

Read more

-

- Vision & Barcode Inspection

- Ensure Allergen-Free Products. Validate Components & Print Seamlessly while Detecting Errors & Preventing Defects.

Read more