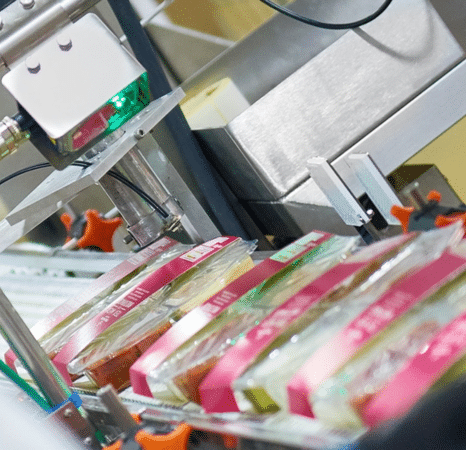

Barcode Inspection

Harford Barcode Inspection Solutions include 1D, 2D and QR barcode verification, ensuring the correct matching of component parts to products. This guarantees accurate, reliable and compliant barcode scanning and verification.

Ensuring Compliance with Barcode Inspection Systems

Harford barcode inspection solutions often empower manufacturers to ensure accurate, reliable and compliant barcode scanning and verification. Our barcode inspection solutions contain 1D, 2D and QR barcode verification capabilities, ensuring the matching of the right component parts to the right products. By detecting barcode errors and ensuring compliance, our solutions enable businesses to optimise processes, minimise risks, and deliver products with precision and confidence.

Enhanced Accuracy, Improved Traceability & Version Control

Harford barcode inspection solutions provide convenient packaging verification, automated component matching, increased traceability, version control, and the inclusion of additional customer information. With enhanced accuracy, reduced wastage, and improved traceability, our solutions empower manufacturers to optimise operations, minimise disruptions, and build customer trust.

Effective Barcode Tracking and Analysis

Harford barcode inspection solutions include component matching for accurate assembly, reducing errors and raw material wastage. Our solutions enable effective barcode tracking and analysis by providing visibility and traceability. Harford barcode inspection solutions comply with industry codes of practice, ensuring adherence to standards. Our barcode inspection solutions contain 1D, 2D and QR barcode verification for accurate and reliable data capture.

2D v 1D (EAN) Codes

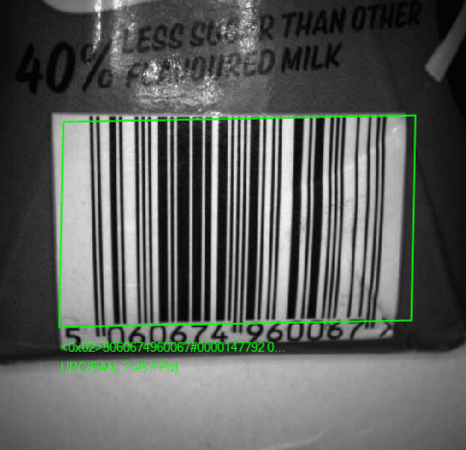

Traditional, one-dimensional barcodes (e.g. EAN-8 or EAN-13) can only contain a limited amount of numbers. Due to two-dimensional data storage, DataMatrix codes can contain up to 2335 alphanumeric characters. The increased density and capacity of information enables much more versatile applications than conventional barcodes. However, for accurate and reliable online reading at speed, it is important to keep the number of characters to a minimum.

Boosting Customer Trust through Barcode Inspection Systems

Barcode Inspection is vital in businesses where accurate product identification, traceability, and compliance are critical. Barcode accuracy supports product identity, supply chain integrity, and regulatory compliance in the FMCG, Food & Beverage, Health & Beauty, Pharmaceutical and Chemical industries. Implementing barcode inspection solutions helps manufacturers in meeting industry requirements, improving operational efficiency and in maintaining customer trust.

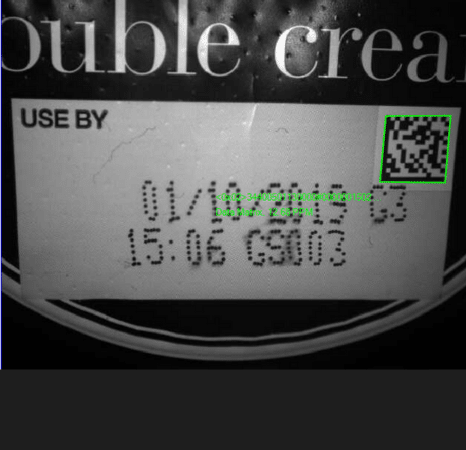

High Information Density 2D or QR Codes

Information can be placed in a small area, e.g. packaging component, version control data

Digital Information Encoding

As opposed to the analogue encoding of data in conventional barcodes i.e.alphabetic characters and numbers stored

Omni-Directional Reading

Can be read in any orientation as they are read by video cameras

Integrated Error Correction

Even on occasions when the barcode is damaged, the overall content may still be readable

Scalable and Printable

They are scaleable and can be printed and read in various levels of magnification with resolution limits dependent upon the automation speed

Barcode Inspection - Why Work with Harford Control?

With our deep understanding of industry requirements, expertise in barcode scanning technologies, and commitment to customer success, we deliver tailored solutions that address specific needs.

Harford provides free and insightful advice and support, to help you choose the optimum size, location and colour of barcode for your specific application. We can also test your codes before final print.

Who We Have Helped

FAQs

-

What is barcode inspection in manufacturing?

Barcode inspection is the process of using specialized equipment, such as barcode scanners or vision systems, to read and verify the accuracy of barcodes on products, components, or packaging. It ensures that barcodes are correctly printed, readable, and contain accurate information for efficient tracking, inventory management, and supply chain operations.

-

Why is barcode inspection important in manufacturing?

Barcode inspection is important in manufacturing because barcodes play a critical role in product identification, traceability, and inventory management. Barcode inspection ensures that the barcodes are legible, correctly encoded, and conform to industry standards. It helps prevent errors, improve operational efficiency, and enhance data accuracy throughout the manufacturing and distribution processes.

-

What types of barcodes can be inspected?

Barcode inspection systems can inspect various types of barcodes, including linear barcodes (such as UPC, EAN, Code 128) and 2D barcodes (such as QR codes, Data Matrix). The systems can validate the structure, content, and readability of the barcodes, ensuring they meet the required standards for effective scanning and data capture.

-

Can barcode inspection systems handle high-speed production lines?

Yes, barcode inspection systems are designed to handle high-speed production lines. They are equipped with fast scanning capabilities and advanced image processing algorithms to quickly read and verify barcodes in real-time. Barcode inspection systems can keep pace with high-speed manufacturing environments, ensuring efficient barcode verification without compromising accuracy or productivity.

-

How does barcode inspection help with product traceability?

Barcode inspection plays a crucial role in product traceability by ensuring accurate and reliable barcode data. It enables manufacturers to track and trace products throughout the supply chain, from production to distribution. Barcode inspection helps maintain a robust traceability system, enabling quick and accurate identification, recall management, and quality control in case of any issues or recalls.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.