Performance Analysis

Harford Performance Analysis Solutions provide real-time actionable information for manufacturers, helping them uncover issues and wastage, drive efficiency and achieve operational excellence. These solutions include OEE/Operational Efficiency, Short Interval Control, Live Reporting, Centrelining and End-to-End Traceability.

Manufacturing Performance Analysis Solutions

Performance analysis is a crucial aspect of optimising manufacturing and production processes. At Harford Control, we provide cutting-edge integrated solutions for performance analysis that help businesses uncover insights, drive efficiency and achieve operational excellence.

Our integrated suite of tools empowers manufacturers to monitor performance metrics, identify bottlenecks, make data-driven decisions and continuously improve performance.

Real Time Visibility and Data Analysis

You can’t improve what you can’t see.

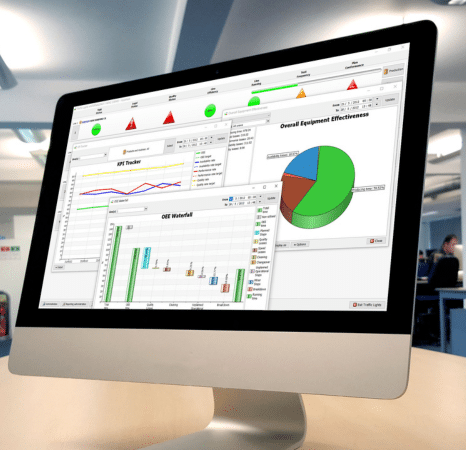

Harford performance analysis solutions offer a range of features and benefits to manufacturers. They provide real-time visibility and turn data analysis into key performance indicators so businesses can make the most informed decisions. By leveraging advanced OEE/Operational Efficiency, Short Interval Control and Live Reporting, we help manufacturers reduce wastage, improve manufacturing performance and reduce transformational costs.

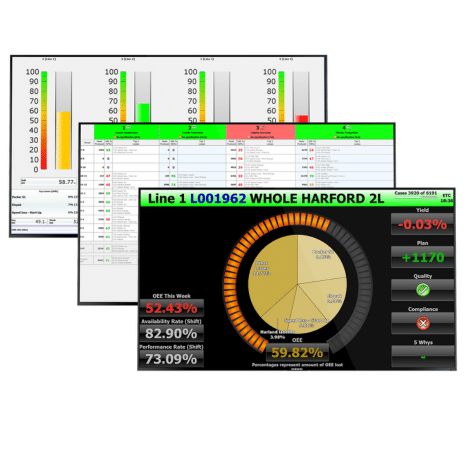

OEE/Operational Efficiency

Harford OEE/Operational Efficiency solutions offer automated, precise, and real-time information, empowering each team to make timely decisions based on factual data rather than opinions and guesswork. Our line performance solutions provide a flexible and user-friendly interface, ensuring complete visibility of your manufacturing processes in real time, whether you are onsite or working remotely.

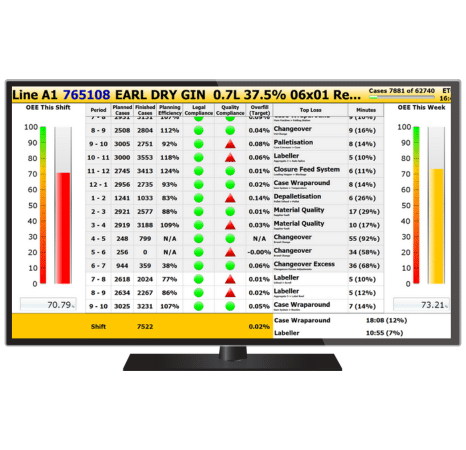

Short Interval Control

Harford Short Interval Control (SIC) solutions turn days into hourly real-time events, typically displaying on large 50″ screens, even in stainless steel, waterproof housings where the business dictates, across the production facility. Quick and focused reviews during the shift enable mid-batch corrections and immediate fixes. Our solutions have been proven to help manufacturers enhance focus, OEE, operator engagement, and identify performance improvement opportunities, thereby reducing wastage and unit costs.

Live Reporting

Harford Live Reporting Solutions combine factory screens, PCs, tablets and Smart phones to draw instant attention to current state and actions required. With up-to-date information at their fingertips, stakeholders frequently make informed decisions, take appropriate corrective actions, and drive continuous improvement across manufacturing.

Centrelining

As there is only one ideal production line set-up for each product/line combination, Harford’s Centerlining helps manufacturers to return all settings to the optimum. During production runs, various adjustments and well meaning tweaks to ‘fix’ production problems are often seen as normal, but can leave production line set-ups far below the optimum. Harford’s Centrelining helps to correct this.

Why Work with Harford Control?

Over several decades, Harford Control has worked tirelessly with a wide range of factories across five continents to help optimise their production performance.

With the Harford Manufacturing Execution System (MES) tailored to individual needs, it becomes easier to reduce errors, find the hidden wastage and consequently become more efficient, whilst continuing to deliver consistently high quality products, thereby making each business more profitable and sustainable.

Most manufacturers are facing ever increasing input and transformation costs with few opportunities to increase the output price to their customers (High Street Multiples).

This encourages manufacturers to look more deeply into their production processes to find the hidden costs, eliminate wastage and thereby improve efficiency without compromising quality.

The problem of rising input costs and fixed output costs is nothing new and will not end. Therefore performance improvement to drive down transformation costs must be continuous for the business to sustain its market position and avoid losing its place on supermarket shelves to the competition.

Who We Have Helped

FAQs

-

What is performance analysis in manufacturing?

Performance analysis in manufacturing involves the systematic evaluation of key performance indicators (KPIs) and metrics to assess the efficiency and effectiveness of production processes. It helps identify areas of improvement, optimize resource utilization, and enhance overall operational performance.

-

What are the common KPIs used in performance analysis?

Common KPIs used in performance analysis include overall equipment effectiveness (OEE), cycle time, production yield, downtime, scrap rates, quality metrics, and labour productivity. These indicators provide insights into various aspects of manufacturing performance and help measure efficiency, productivity, and quality levels.

-

How does performance analysis benefit manufacturing companies?

Performance analysis provides valuable insights for manufacturing companies to identify bottlenecks, inefficiencies, and improvement opportunities in their operations. It enables data-driven decision-making, facilitates continuous improvement initiatives, optimizes resource allocation, reduces costs, and enhances overall productivity and profitability.

-

What tools or software are used for performance analysis?

Performance analysis in manufacturing often involves the use of specialized software and tools that collect, analyse, and visualize production data. These tools can include manufacturing execution systems (MES), data analytics platforms, dashboard reporting software, and business intelligence (BI) tools. They help monitor KPIs, track performance trends, and generate actionable insights for improvement.

-

How can performance analysis help optimize production processes?

Performance analysis helps optimize production processes by identifying areas of inefficiency, such as bottlenecks, machine downtime, or quality issues. By analysing performance data, manufacturers can implement targeted process improvements, streamline workflows, allocate resources effectively, and reduce waste. It enables continuous process optimization and supports lean manufacturing principles.